How Custom Pond Pumps Are Manufactured: Materials & Seals Explained

Why Customization Matters in Pond Pumps

In the world of aquatic systems—from koi ponds to large-scale filtration setups—one-size-fits-all pumps often fall short. That's where custom pond pumps come in. By tailoring components like materials, seals, and motor configurations, a custom pond pump ensures optimal flow, corrosion resistance, and long-term durability.

At Jinwa Aquatics, we specialize in engineering and manufacturing custom pond pumps designed for professional aquatics, aquaculture, landscaping, and water feature applications.

1. Material Selection: Building a Pump That Lasts

Choosing the right materials for pump construction directly affects performance and longevity. Jinwa Aquatics helps clients select the ideal combinations based on water chemistry, flow rate, and environment.

- Pump Housing: Glass-filled polypropylene or stainless steel

- Impellers: Noryl, bronze, or ceramic-reinforced plastics

- Pump Shaft: Stainless steel or ceramic-coated options

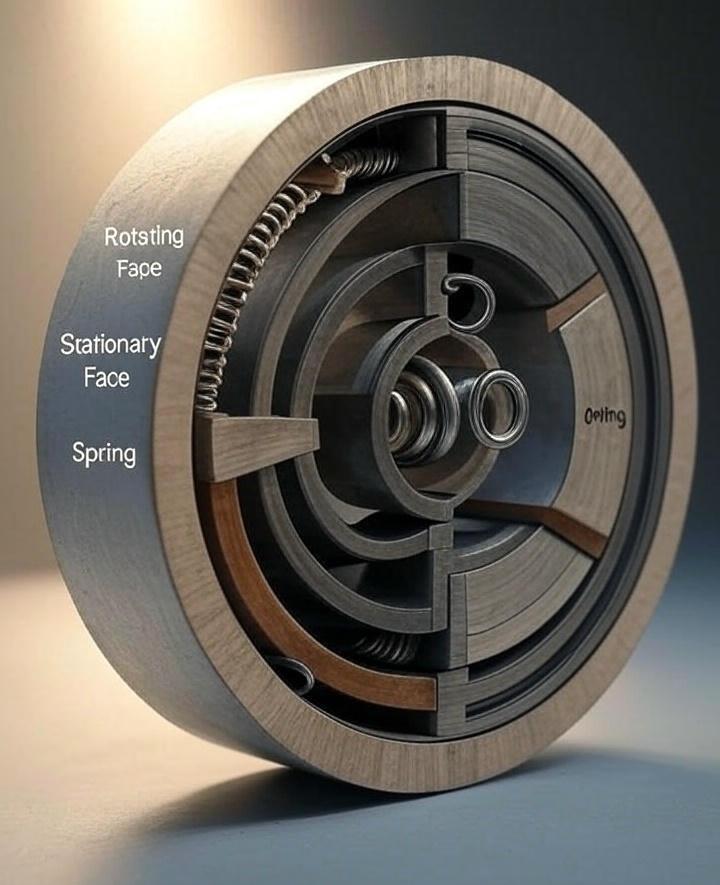

2. Understanding Mechanical Seals

Mechanical seals prevent water leakage along the motor shaft. Seal type and material must be matched to your pond’s water conditions and pump configuration.

- Rotating Faces: Silicon carbide, carbon graphite

- Stationary Faces: Ceramic, tungsten carbide

- O-Rings: Viton, EPDM, PTFE

Jinwa Aquatics offers advanced seal configurations including double mechanical seals and magnetic drive systems.

3. From Concept to Completion

The custom pump manufacturing process includes:

- Engineering & Simulation: CAD/CFD modeling for flow and pressure

- Material Machining: CNC precision to ±0.02mm

- Seal Integration & Testing: Pressure and leak testing

- Final Assembly: Performance validation under pond conditions

4. Application-Specific Customizations

Why Choose Jinwa Aquatics?

- ✔ 15+ years of pump manufacturing expertise

- ✔ ISO-certified, in-house production

- ✔ OEM/ODM solutions with fast prototyping

- ✔ Global delivery & multilingual support

Contact us today: jinwa-aquatics.com/contact-us