Label Customization

Label customization is the process of imprinting the product with the name and logo of the business in charge of custom creation. You can have your company name, logo and any other identifying information you want to include on the product.

You can collaborate with Jinwa's designers to build a unique design that meets your requirements or you can supply artwork or graphic files that incorporate your branding.

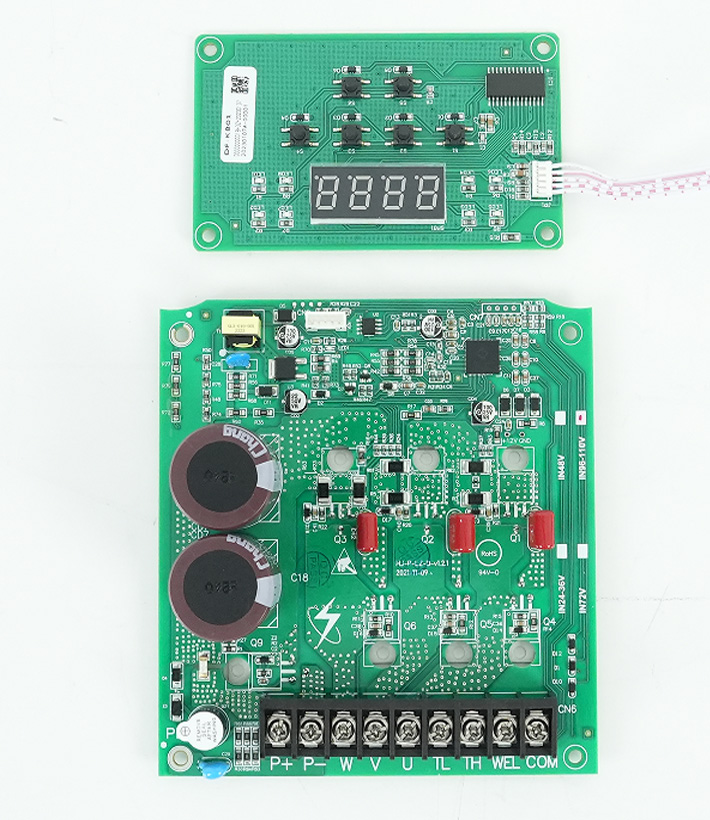

The Variable Speed Pumps, controller, and packaging will all have the finished label applied to them during manufacture so that they are prepared to be shipped to you or your clients as a completely branded product.