ICT Testing

Every circuit board must be tested by ICT to detect the defective rate and failure rate of components.

SPI machine checks the amount of solder paste on the PCB and the uniformity of the solder paste coating.

AOI machine scans and inspects the PCB to ensure the correct placement of all components.

Every circuit board must be tested by ICT to detect the defective rate and failure rate of components.

Every circuit board must be connected to a water pump for FCT testing to ensure the stability of product quality.

Every circuit board must undergo a long-term high temperature resistance and aging test to ensure the quality of the controller.

Processing the oil cylinder, connection and water outlet with CNC lathe to guarantee the size and appearance of products.

Drilling and thread tapping with Machining Center , to ensure product quality, efficiency and precision.

Process the rotor shaft and shaft teeth. The robot controls the loading and unloading, reducing labor and improving efficiency.

Three drilling and tapping centers work at the same time to produce and process the controller shells, with small machining accuracy error and high product qualification rate and consistency.

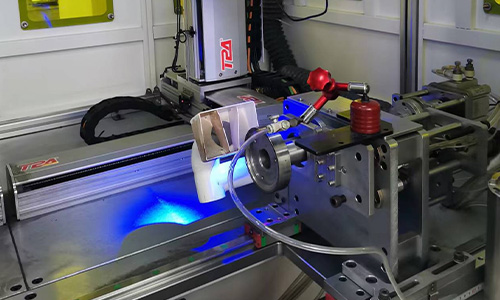

Welding shielded motor with fully automatic laser welding equipment to ensure the smoothness and tightness of the weld seam of the water pump after welding, thereby enhancing the reliability of the motor.

Adopt precision machining to ensure the accuracy and concentricity of the key dimensions of the rotor.

Difful is committed to maintaining high quality standards throughout all of our products and services. We continuously improve our design, manufacturing process and product quality to provide the best product performance and achieve "Zero Defect" in our daily operations.

Our goal is to provide satisfactory and effective customer support, on-time delivery and suitable features at the right price.

NO.1

NO.1Inter-turn and withstand voltage test of coil winding.

Make sure that there is no open circuit or short circuit fault in the winding.

NO.2

NO.2Check the installation accuracy of the rotor shaft to ensure the consistency of the height of the motor shaft head.

NO.3

NO.3Check the speed, steering, withstand voltage, and inter-turn of the motor.

NO.4

NO.4The air tightness test of the motor ensures that the motor has no water leakage.

NO.5

NO.5Finished product test to check the motor speed, steering, and the serial momentum of the pump body.

NO.6

NO.6Simulate the real solar operation to ensure the authenticity of the pump head flow data.

NO.7

NO.7Inspection of the water pump appearance and brand label.

NO.8

NO.8Inspection of water pumps, controllers, accessory kits, manuals, etc. before packing .

Products include DC solar water pumps, AC-DC hybrid solar water pumps, shielded motor solar water pumps. Since our founding in 1989 we have been 100% dedicated to this field and we have hundreds of thousands of pumps in use around the world. We have high precision and fully automatic processing machines, advanced assembly lines and testing machines to improve quality and efficiency. And we have established our own controller production and R&D workshops to ensure that every production process is under control. Difful independently produces controllers and important components of solar water pumps. Better cost control provides customers with greater profit margins. We have a professional team working in the field of solar water pumps for more than 10 years. Our production team is very rigorous and professional, and every product they produce maintains high quality and high standards. We want to provide the best products to the world. Obtain energy from sunlight, transfer water from nature, and serve life. This has always been Difful's vision.

1800V withstand voltage test of the coil, 40m underwater withstand voltage test of the motor, performance test and appearance inspection of the whole machine. All products are 100% quality inspected.

Yes. DIFFUL SOLAR PUMP has Intelligent water shortage protection function. The pump stops working automatically when there is no water in the well, and automatically start working 30 minutes later. The whole process does not require manual operation and is completed automatically.

The solar pumps use a 4 core or 3 core cable and needs to be sized correctly based on the size of the solar pump required as well as the total cable distance. This is to ensure that the pumps performance does not get affected by volt drop over the cable distance. As long as the diameter requirements are met, the existing cables on the AC pump can also be used for solar pumps.

1800V withstand voltage test of the coil, 40m underwater withstand voltage test of the motor, performance test and appearance inspection of the whole machine. All products are 100% quality inspected.

1800V withstand voltage test of the coil, 40m underwater withstand voltage test of the motor, performance test and appearance inspection of the whole machine. All products are 100% quality inspected.

1800V withstand voltage test of the coil, 40m underwater withstand voltage test of the motor, performance test and appearance inspection of the whole machine. All products are 100% quality inspected.